Cov khoom

-

Cam khwb cia tooj liab flange

Khoom nthuav qhia:

Flange kuj hu ua flange los yog flange.Ib feem uas interconnects ib tug yeeb nkab mus rau ib tug yeeb nkab, txuas nrog ib tug yeeb nkab kawg.Muaj qhov nyob rau hauv lub flange thiab lub bolts fasten ob flanges ua ke.Gasket ntawm flanges.Flange yog ib hom disk, nyob rau hauv cov kav dej engineering feem ntau, flanges yog siv ua khub.In piping engineering, flanges yog siv rau kev sib txuas piping.Nruab ib flange ntawm txhua qhov kawg ntawm ob lub kav dej.Cov kav dej uas tsis tshua muaj siab tuaj yeem txuas nrog hlau flange.Vuam flange yog siv rau lub siab ntawm ntau tshaj 4kg.Tau ib lub gasket ntawm ob flanges thiab ntsia liaj qhov rooj.

Flanges ntawm qhov sib txawv siab muaj qhov sib txawv tuab thiab siv cov bolts sib txawv.

Cov twj tso kua mis thiab cov li qub, thaum txuas nrog cov yeeb nkab, qhov chaw ntawm cov khoom siv no kuj tau ua rau cov flange zoo sib xws, tseem hu ua flange txuas.

General nyob rau hauv ob lub dav hlau nyob rau hauv periphery ntawm kev siv bolts thiab kaw qhov kev twb kev txuas qhov chaw, feem ntau hu ua "flange", xws li lub qhov cua yeeb nkab kev twb kev txuas, qhov zoo ntawm qhov no yuav hu ua "flange part".

Threaded flange yog ib hom flange.Cov xov flange kev twb kev txuas qauv yog ib qho kev sib dhos, uas yog tsim los ntawm ib khub ntawm flanges, ob peb bolts, ceev thiab gasket.

Khoom Taw Qhia:

1/2 "--30" threaded flange

Suav cov qauv:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

SH406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB / T13402-92 -

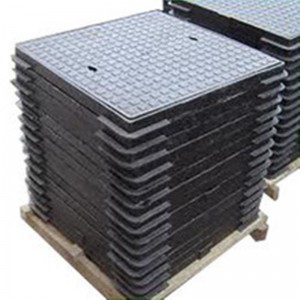

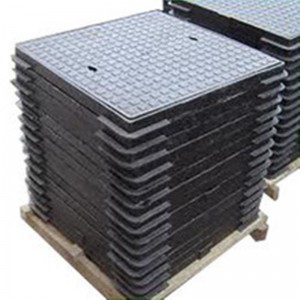

Manhole npog

Khoom nthuav qhia:

Zoo toughness.Qhov cuam tshuam tus nqi zoo ib yam li cov khoom nruab nrab carbon steel, uas yog ntau tshaj 10 npaug ntawm cov khoom siv grey hlau.

Muaj zog corrosion kuj.Nyob rau hauv cov dej tsuag tshuaj tiv thaiv corrosion, tus nqi corrosion nyob rau hauv 90 hnub tsuas yog 1/40 ntawm cov yeeb nkab steel thiab 1/10 ntawm grey hlau yeeb nkab.Qhov kev pab cuam lub neej yog 2 zaug ntawm grey hlau yeeb nkab thiab 5. lub sij hawm zoo tib yam steel yeeb nkab.

Zoo plasticity.Elongation ≥7%, zoo ib yam li cov pa roj carbon siab, tab sis grey hlau cov khoom elongation yog xoom.

Lub zog siab.Qhov tensile lub zog ob ≥420MPa thiab tawm los lub zog OS ≥300MPa yog tib yam li cov pa roj carbon tsawg thiab peb zaug li cov khoom siv hlau grey.

Vim nws cov nodular graphite microstructure, ductile hlau yog zoo dua cam khwb cia hlau nyob rau hauv txo kev co muaj peev xwm, yog li nws muaj txiaj ntsig zoo los txo cov kev ntxhov siab.Ib qho laj thawj tseem ceeb rau kev xaiv cov hlau ductile yog cov hlau ductile nqi tsawg dua cam khwb cia hlau. hlau ua rau cov khoom no nrov dua, ua haujlwm zoo dua, thiab tsis tshua muaj nqi rau lub tshuab.

Lub zog ntawm ductile hlau yog piv rau cov hlau cam khwb cia hlau.Ductile hlau muaj lub zog tawm los ntau dua, nrog qhov tsawg kawg nkaus lub zog ntawm 40K thiab cam khwb cia steel yield zog ntawm tsuas yog 36K.Ductile hlau yog ntau resistant rau corrosion thiab oxidation dua cam khwb cia hlau nyob rau hauv feem ntau siv hauv nroog xws li dej, dej ntsev, chav dej, thiab lwm yam.

-

Cam khwb cia hlau manhole npog

Khoom nthuav qhia:

Zoo toughness.Qhov cuam tshuam tus nqi zoo ib yam li cov khoom nruab nrab carbon steel, uas yog ntau tshaj 10 npaug ntawm cov khoom siv grey hlau.

Muaj zog corrosion kuj.Nyob rau hauv cov dej tsuag tshuaj tiv thaiv corrosion, tus nqi corrosion nyob rau hauv 90 hnub tsuas yog 1/40 ntawm cov yeeb nkab steel thiab 1/10 ntawm grey hlau yeeb nkab.Qhov kev pab cuam lub neej yog 2 zaug ntawm grey hlau yeeb nkab thiab 5. lub sij hawm zoo tib yam steel yeeb nkab.

Zoo plasticity.Elongation ≥7%, zoo ib yam li cov pa roj carbon siab, tab sis grey hlau cov khoom elongation yog xoom.

Lub zog siab.Qhov tensile lub zog ob ≥420MPa thiab tawm los lub zog OS ≥300MPa yog tib yam li cov pa roj carbon tsawg thiab peb zaug li cov khoom siv hlau grey.

Vim nws cov nodular graphite microstructure, ductile hlau yog zoo dua cam khwb cia hlau nyob rau hauv txo kev co muaj peev xwm, yog li nws muaj txiaj ntsig zoo los txo cov kev ntxhov siab.Ib qho laj thawj tseem ceeb rau kev xaiv cov hlau ductile yog cov hlau ductile nqi tsawg dua cam khwb cia hlau. hlau ua rau cov khoom no nrov dua, ua haujlwm zoo dua, thiab tsis tshua muaj nqi rau lub tshuab.

Lub zog ntawm ductile hlau yog piv rau cov hlau cam khwb cia hlau.Ductile hlau muaj lub zog tawm los ntau dua, nrog qhov tsawg kawg nkaus lub zog ntawm 40K thiab cam khwb cia steel yield zog ntawm tsuas yog 36K.Ductile hlau yog ntau resistant rau corrosion thiab oxidation dua cam khwb cia hlau nyob rau hauv feem ntau siv hauv nroog xws li dej, dej ntsev, chav dej, thiab lwm yam.

-

Kev cai grate

Khoom nthuav qhia:

Grizzley grate yog ib pab pawg ntawm cov cam khwb cia hlau grate siv los npog grate, pits, thiab lwm yam kev tiv thaiv grate uas tiv thaiv ib tug neeg txoj kev nyab xeeb los yog tiv thaiv ntoo thiab lwm yam kev tiv thaiv los ntawm kev puas tsuaj.

Cov gratings yog cov nag gratings, ntoo gratings, grating gratings, pem teb gratings, thiab lwm yam.Piv txwv li, hlau grates feem ntau muab tso rau ntawm lub qhov dej ntawm chav da dej, tso cai rau cov dej ntws mus rau hauv thiab tiv thaiv kev raug mob ntawm ko taw thiab ko taw.

-

Resin npog

Khoom nthuav qhia:

1. Muaj zog tiv thaiv kev ua tub sab: resin composite khoom manhole npog siv unsaturated resin, iav fiber ntau thiab lwm yam khoom siv thiab cov pob txha siv zog ntxiv los ntawm cov txheej txheem tsim tshwj xeeb, tom qab kub kub thiab nias rau kev tsim, cov khoom siv rov ua dua tshiab, nws yog qhov nyuaj heev. tshem tawm cov hlau bar (kwv tawm tus nqi ntawm cov nqi hlau ntau dua li cov hlau) yog li nws muaj kev ua haujlwm tiv thaiv tub sab nyiag.

2. Cov kabmob muaj peev xwm loj: hauv qab ntawm lub lauj kaub tshwj xeeb hauv qab qauv, kom thaj tsam kev ntxhov siab tau nce kaum zaug lossis txawm tias kaum ob lub sijhawm.Cov khoom siv txuas ntxiv txuas ntxiv yog siv los xyuas kom meej cov fiber ntau fiber ntau thiab iav fiber ntau cov ntaub sib xyaw ua ke hauv cov khoom siv, kom cov khoom muaj peev xwm nqa tau txaus.Thiab ua tau raws li cov qauv hauv tebchaws.

3. Lub neej ua haujlwm ntev, los ntawm kev siv cov khoom siv siab, iav fiber ntau thiab cov mis tshwj xeeb, cov txheej txheem tsim khoom kom paub meej tias kev nkag mus ntawm resins hauv iav fiber ntau, txhim kho cov nplaum relay zoo heev, ua rau cov khoom siv nyob rau hauv cyclic loading, tsis tsim sab hauv. kev puas tsuaj, thiaj li ua kom lub neej kev pab cuam ntawm cov khoom, thiab lwm yam resin composite manhole npog nrog tib qhov zoo.Tau xaus rau qhov tsis zoo ntawm cov adhesion tsis zoo.

4. Zoo nkauj thiab ua tau zoo, qib siab: Raws li cov kev xav tau ntawm cov neeg siv khoom siab, peb tuaj yeem ua cov LOGO complex thiab ntau yam xim ntawm tib lub manhole npog saum npoo ntawm tus kheej tsim, kom cov qauv yog ilv, ci xim, distinct.Thiab tuaj yeem ua raws li cov neeg siv khoom xav tau thiab txhua yam ntawm cov pob zeb pavement tib yam imitation pob zeb nto thiab xim.

5. High / low temperature resistance, zoo rwb thaiv tsev thiab muaj zog corrosion kuj: corrosion kuj, non-toxic thiab harmless.No hlau additives, ua si ib tug tiag tiag kev txiav txim zoo ntawm rwb thaiv tsev nyhuv. Cov khoom tau raug soj ntsuam los ntawm cov koom haum soj ntsuam muaj cai hauv lub tebchaws, nrog rau cov kua qaub thiab alkali tsis kam, corrosion resistance, anti-aging thiab lwm yam ntsuas tau mus txog thiab dhau lub teb chaws tus qauv.

6. Kev tiv thaiv ib puag ncig, tiv thaiv kev nplua, tsis tshua muaj suab nrov: cov khoom yuav tsis plam, tsis muaj suab nrov thiab rov qab tshwm sim tom qab lub tsheb khiav dhau.Tam sim no, vim lub teeb yuag ntawm cov khoom, npog, lub rooj zaum buckle precision , kov yeej lwm yam kev soj ntsuam npog "dhia, stilt, suab, hloov chaw" thiab lwm yam teeb meem.

-

Kev cai flange

Khoom nthuav qhia:

Flange kuj hu ua flange los yog flange.Ib feem uas interconnects ib tug yeeb nkab mus rau ib tug yeeb nkab, txuas nrog ib tug yeeb nkab kawg.Muaj qhov nyob rau hauv lub flange thiab lub bolts fasten ob flanges ua ke.Gasket ntawm flanges.Flange yog ib hom disk, nyob rau hauv cov kav dej engineering feem ntau, flanges yog siv ua khub.In piping engineering, flanges yog siv rau kev sib txuas piping.Nruab ib flange ntawm txhua qhov kawg ntawm ob lub kav dej.Cov kav dej uas tsis tshua muaj siab tuaj yeem txuas nrog hlau flange.Vuam flange yog siv rau lub siab ntawm ntau tshaj 4kg.Tau ib lub gasket ntawm ob flanges thiab ntsia liaj qhov rooj.

Flanges ntawm qhov sib txawv siab muaj qhov sib txawv tuab thiab siv cov bolts sib txawv.

Cov twj tso kua mis thiab cov li qub, thaum txuas nrog cov yeeb nkab, qhov chaw ntawm cov khoom siv no kuj tau ua rau cov flange zoo sib xws, tseem hu ua flange txuas.

General nyob rau hauv ob lub dav hlau nyob rau hauv periphery ntawm kev siv bolts thiab kaw qhov kev twb kev txuas qhov chaw, feem ntau hu ua "flange", xws li lub qhov cua yeeb nkab kev twb kev txuas, qhov zoo ntawm qhov no yuav hu ua "flange part".

Threaded flange yog ib hom flange.Cov xov flange kev twb kev txuas qauv yog ib qho kev sib dhos, uas yog tsim los ntawm ib khub ntawm flanges, ob peb bolts, ceev thiab gasket.

Khoom Taw Qhia:

1/2 "--30" threaded flange

Suav cov qauv:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

SH406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB / T13402-92 -

Hlau flange

Khoom nthuav qhia:

Flange kuj hu ua flange los yog flange.Ib feem uas interconnects ib tug yeeb nkab mus rau ib tug yeeb nkab, txuas nrog ib tug yeeb nkab kawg.Muaj qhov nyob rau hauv lub flange thiab lub bolts fasten ob flanges ua ke.Gasket ntawm flanges.Flange yog ib hom disk, nyob rau hauv cov kav dej engineering feem ntau, flanges yog siv ua khub.In piping engineering, flanges yog siv rau kev sib txuas piping.Nruab ib flange ntawm txhua qhov kawg ntawm ob lub kav dej.Cov kav dej uas tsis tshua muaj siab tuaj yeem txuas nrog hlau flange.Vuam flange yog siv rau lub siab ntawm ntau tshaj 4kg.Tau ib lub gasket ntawm ob flanges thiab ntsia liaj qhov rooj.

Flanges ntawm qhov sib txawv siab muaj qhov sib txawv tuab thiab siv cov bolts sib txawv.

Cov twj tso kua mis thiab cov li qub, thaum txuas nrog cov yeeb nkab, qhov chaw ntawm cov khoom siv no kuj tau ua rau cov flange zoo sib xws, tseem hu ua flange txuas.

General nyob rau hauv ob lub dav hlau nyob rau hauv periphery ntawm kev siv bolts thiab kaw qhov kev twb kev txuas qhov chaw, feem ntau hu ua "flange", xws li lub qhov cua yeeb nkab kev twb kev txuas, qhov zoo ntawm qhov no yuav hu ua "flange part".

Threaded flange yog ib hom flange.Cov xov flange kev twb kev txuas qauv yog ib qho kev sib dhos, uas yog tsim los ntawm ib khub ntawm flanges, ob peb bolts, ceev thiab gasket.

Khoom Taw Qhia:

1/2 "--30" threaded flange

Suav cov qauv:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

SH406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB / T13402-92 -

Kev cai forged qhov chaw

Khoom nthuav qhia:

Lub tshuab forging yog siv los tsim cov yas deformation los ntawm exerting siab ntawm cov hlau dawb paug kom tau qhov forging nrog qee yam khoom siv, cov duab thiab qhov loj.Los ntawm qhov nruam hammering ntawm cov yeeb nkab haum, cov thawj segregation, porosity, porosity, slag thiab lwm yam compaction thiab Kev sib koom ua ke hauv lub ingot ua ntau dua, thiab cov yas thiab cov khoom siv ntawm cov hlau tau zoo tuaj.Forging yeeb nkab fittings feem ntau suav nrog forging flange, forging txo cov yeeb nkab, forging tee, thiab lwm yam.Cov ntaub ntawv tseem ceeb ntawm forged yeeb nkab fittings yog Q235, Q345, 16Mn. , 20 #, 35 #, 45 #, 40Cr, 12Cr1MoV, 30CrMo, 15CrMo, 20G, thiab lwm yam.Nrog rau cov forging fittings yog casting haum, txhua yam khoom ntawm castings hauv qab forgings nrog tib cov khoom siv kho tshuab, casting yeeb nkab fittings hlau melting rau hauv Ua raws li cov kev cai ntawm cov kua thiab nchuav rau hauv pwm, tom qab txias solidification, cov txiv neej tau txais ib tug predetermined zoo, loj thiab kev ua tau zoo ntawm cov casting qhov chaw (los yog bl.ank) txheej txheem[1]

-

Forging steel yeeb nkab

Khoom nthuav qhia:

Lub tshuab forging yog siv los tsim cov yas deformation los ntawm exerting siab ntawm cov hlau dawb paug kom tau qhov forging nrog qee yam khoom siv, cov duab thiab qhov loj.Los ntawm qhov nruam hammering ntawm cov yeeb nkab haum, cov thawj segregation, porosity, porosity, slag thiab lwm yam compaction thiab Kev sib koom ua ke hauv lub ingot ua ntau dua, thiab cov yas thiab cov khoom siv ntawm cov hlau tau zoo tuaj.Forging yeeb nkab fittings feem ntau suav nrog forging flange, forging txo cov yeeb nkab, forging tee, thiab lwm yam.Cov ntaub ntawv tseem ceeb ntawm forged yeeb nkab fittings yog Q235, Q345, 16Mn. , 20 #, 35 #, 45 #, 40Cr, 12Cr1MoV, 30CrMo, 15CrMo, 20G, thiab lwm yam.Nrog rau cov forging fittings yog casting haum, txhua yam khoom ntawm castings hauv qab forgings nrog tib cov khoom siv kho tshuab, casting yeeb nkab fittings hlau melting rau hauv Ua raws li cov kev cai ntawm cov kua thiab nchuav rau hauv pwm, tom qab txias solidification, cov txiv neej tau txais ib tug predetermined zoo, loj thiab kev ua tau zoo ntawm cov casting qhov chaw (los yog bl.ank) txheej txheem[1]