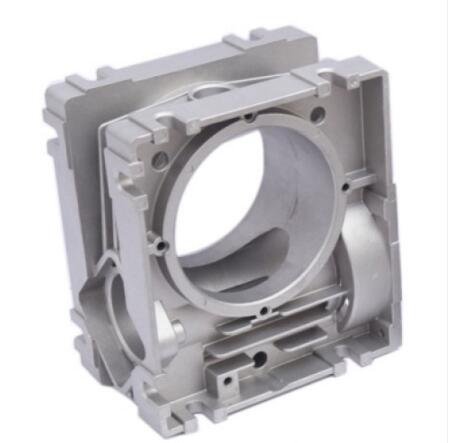

Nres disc / Brack rotor

| Khoom siv | Aluminium: AL6061, AL6063, AL6082, AL7075, AL5052, AL2024 |

| Stainless hlau: SS201, SS301, SS303, SS304, SS316, SS430 thiab lwm yam | |

| Hlau: me me hlau / carbon hlau xws li 1010, 1020, 1045, 1050, Q690 thiab lwm yam | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 thiab lwm yam. | |

| Tooj: C11000, C12000, C12000, C17200, C72900, C36000 thiab lwm yam. | |

| Kev ua haujlwm | Lub teb chaws Yelemees Trumpf hom Laser cutter, CNC shearing tshuab, CNC dabtsi yog khoov tshuab, |

| (CNC) stamping tshuab, Hyraulic Tshuab, Ntau yam vuam tshuab, CNC tshuab center. | |

| Nto | Aluminium: Anodization, Sandblast, Txhuam, Polishing, Electro-plating thiab lwm yam |

| Stainless hlau: Polishing, Txhuam, Passivating, Sandblasting, Electro-plating | |

| Hlau: Zinc plating, Nickel plating, Chrome plating, hmoov txheej, painting thiab lwm yam | |

| Brass & Copper: Txhuam, Polishing thiab lwm yam | |

| Precision | + - 0.1 hli |

| Daim ntawv thov | Railway, Tsheb, Tsheb, Kev Kho Mob, Machinery, Khoom Siv Hluav Taws Xob, Hluav Taws Xob thiab lwm yam |

Specification:

Txuj: EN, SAE, GB, DIN

Zoo Standard OEM

Meterial Qib GG 25, HT 250

Tshuaj muaj pes tsawg leeg C: 3.5-3.7 Si: 1.5-2.1% Mn: 0.6-0.9%

P: <0.12% S: <0.1% Cr: 0.6-0.9% Cu: 0.3-0.8

Mechanics kev ua tau zoo tensile zog: ≥250Mpa

Hardness HB180-225

Non-Destructive Test Metallurgical Test

Dimension soj ntsuam dimension soj ntsuam daim ntawv qhia

Kev tsim khoom raws li tus neeg siv khoom kos duab lossis OEM naj npawb

qhov zoo

1, muaj qhov zoo ntawm covnres nres nresmuaj nuj nqi, vim hais tias tus nres ua kom tawm, ua ke nrog kev sib hloov ntawm lub log ntawm lub nruas nres ntawm lub distortion ntawm ib tug foundations (ntawm chav kawm, tab sis tsis loj txaus kom koj tau yooj yim pom) nres rau av nro (dynamic braking system) , qhov ntau dua qhov teeb meem yuav pom tseeb dua, yog li ntawd, feem ntau cov tsheb loj lossis siv lub nruas nres, ntxiv rau cov nqi qis, cov tsheb loj thiab cov tsheb me ntawm lub nruas nres, qhov sib txawv tsuas yog muaj cov mining loj pneumatic auxiliary, thiab cov mining me me nqus auxiliary nres. pab.

2, tus nqi qis: lub nruas nres kev tsim tshuab qib qis, tab sis kuj yog thawj zaug siv hauv lub tshuab nres, yog li tus nqi tsim khoom qis dua lub disc nres.

3, lub installation ntawm tes nres mechanism yog ib qho yooj yim.Qee lub tsheb log nrog disc nres qauv, yuav muab ntsia rau hauv nruab nrab ntawm lub nres disc nruas nres tes nres mechanism.

Txoj kev loj hlob

Vim qhov kev ua tau zoo ntawm lub tsheb thiab kev ceev ntawm lub tsheb nce nrawm, txhawm rau txhawm rau txhim kho kev ruaj ntseg ntawm lub nres thaum lub tsheb khiav ntawm kev kub ceev, lub disc nres tau dhau los ua lub ntsiab ntawm cov nres nres tam sim no.Vim tias lub nres nres. disc ntawm lub disc nres yog raug rau huab cua, lub disc nres muaj zoo heev tshav kub dissipation.Thaum lub tsheb nres nres ntawm kev kub ceev lossis nres ob peb zaug hauv lub sijhawm luv luv, qhov kev ua haujlwm nres tsis yooj yim poob qis, kom lub tsheb tuaj yeem tau txais cov txiaj ntsig zoo dua thiab txhim kho kev nyab xeeb ntawm lub tsheb.Thiab vim yog cov lus teb ceev ceev ntawm lub disc nres, muaj peev xwm ua kom muaj zog nres nres, yog li ntau lub tsheb qauv siv lub disc nres thiab ABS system, VSC, TCS thiab lwm yam, kom tau raws li cov kev xav tau ntawm cov tshuab no xav tau ceev braking.