Titanium alloy qhov chaw tsheb laij teb / Hlau Sand Machinery / Machined Steel / Mechanical / Motor Parts rau Compressor Lub Cev

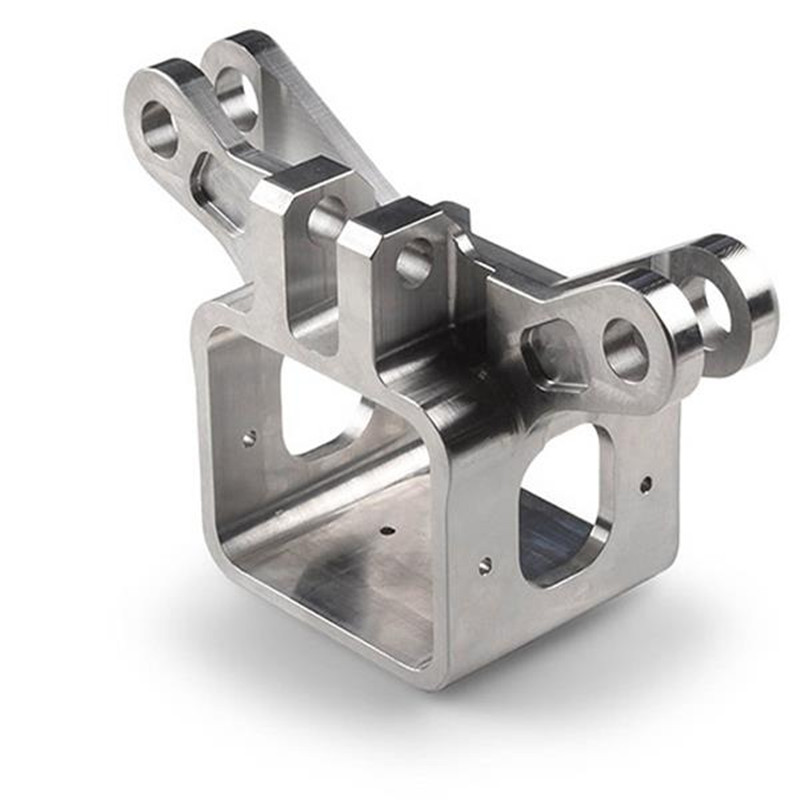

| Khoom siv | Aluminium: AL6061, AL6063, AL6082, AL7075, AL5052, AL2024 |

| Stainless hlau: SS201, SS301, SS303, SS304, SS316, SS430 thiab lwm yam | |

| Hlau: me me hlau / carbon hlau xws li 1010, 1020, 1045, 1050, Q690 thiab lwm yam | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 thiab lwm yam. | |

| Tooj: C11000, C12000, C12000, C17200, C72900, C36000 thiab lwm yam. | |

| Kev ua haujlwm | Lub teb chaws Yelemees Trumpf hom Laser cutter, CNC shearing tshuab, CNC dabtsi yog khoov tshuab, |

| (CNC) stamping tshuab, Hyraulic Tshuab, Ntau yam vuam tshuab, CNC tshuab center. | |

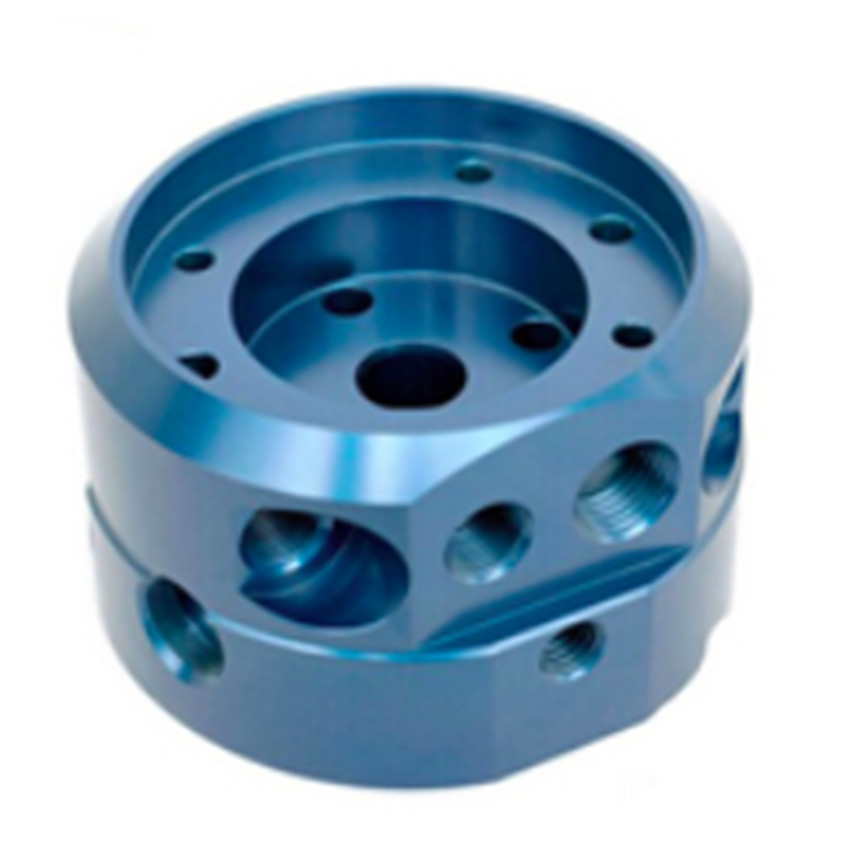

| Nto | Aluminium: Anodization, Sandblast, Txhuam, Polishing, Electro-plating thiab lwm yam |

| Stainless hlau: Polishing, Txhuam, Passivating, Sandblasting, Electro-plating | |

| Hlau: Zinc plating, Nickel plating, Chrome plating, hmoov txheej, painting thiab lwm yam | |

| Brass & Copper: Txhuam, Polishing thiab lwm yam | |

| Precision | + - 0.1 hli |

| Daim ntawv thov | Railway, Tsheb, Tsheb, Kev Kho Mob, Machinery, Khoom Siv Hluav Taws Xob, Hluav Taws Xob thiab lwm yam |

Titanium yog ib hom hlau tshiab.Kev ua haujlwm ntawm titanium muaj feem xyuam rau cov ntsiab lus ntawm impurities xws li carbon, nitrogen, hydrogen thiab oxygen.Cov ntsiab lus ntawm impurities nyob rau hauv lub purest titanium iodide yog tsawg tshaj li 0.1%, tab sis nws lub zog yog tsawg thiab plasticity yog siab. Cov khoom ntawm 99.5% industrial ntshiab titanium yog raws li nram no: ceev ρ = 4.5g / cm3, melting point 1725 ℃, thermal conductivity λ = 15.24W / (mK), tensile lub zog σb = 539MPa, elongation δ = 25%, seem shrinkage ψ = 25%, modulus ntawm elasticity E = 1.078 × 105MPa, hardness HB195.

Siab zog

Qhov ceev ntawm titanium alloy feem ntau yog hais txog 4.51g / cm3, tsuas yog 60% ntawm cov hlau, thiab qee qhov muaj zog titanium alloys siab tshaj lub zog ntawm ntau cov qauv hlau alloy.Yog li ntawd, lub zog tshwj xeeb (lub zog / ntom) ntawm titanium alloy yog ntau dua. dua li ntawm lwm cov khoom siv hlau, uas tuaj yeem tsim qhov chaw nrog lub zog siab, zoo rigidity thiab lub teeb yuag.Aircraft cav Cheebtsam, pob txha, tawv nqaij, fasteners thiab tsaws iav tag nrho siv titanium alloy.

Siab thermal zog

Kev siv kub yog ob peb puas degrees siab dua aluminium alloy, tseem tuaj yeem tuav lub zog xav tau ntawm qhov kub nruab nrab, tuaj yeem ua haujlwm ntev ntawm 450 ~ 500 ℃ kub.Ob hom titanium alloy no nyob rau hauv 150 ℃ ~ 500 ℃ ntau yam tseem muaj lub zog tshwj xeeb, thiab aluminium alloy ntawm 150 ℃ tshwj xeeb lub zog poob qis heev.Qhov kev ua haujlwm kub ntawm titanium alloy tuaj yeem ncav cuag 500 ℃, thaum aluminium alloy yog hauv qab no. 200 ℃.

Zoo tiv thaiv corrosion

Lub corrosion kuj ntawm titanium alloy yog zoo dua li ntawm stainless hlau nyob rau hauv ntub huab cua thiab dej hiav txwv. , sulfuric acid, thiab lwm yam.Tab sis qhov corrosion kuj ntawm titanium kom txo cov pa oxygen thiab chromium nruab nrab tsis zoo.

Kev ua haujlwm kub tsis zoo

Titanium alloy muaj peev xwm tswj tau nws cov cuab yeej cuab tam ntawm qhov qis thiab qis qis.Titanium alloys nrog qhov kub thiab txias kev ua tau zoo thiab cov ntsiab lus qis qis, xws li TA7, tuaj yeem tswj tau qee yam plasticity ntawm -253 ℃.Yog li ntawd, titanium alloy tseem yog ib qho tseem ceeb. Cov khoom siv hluav taws xob tsawg.

Cov tshuaj lom neeg ua haujlwm siab

Titanium alloy cov khoom

Titanium alloy cov khoom

Titanium muaj cov tshuaj lom neeg muaj zog nrog O2, N2, H2, CO, CO2, dej vapor, ammonia thiab lwm yam gases hauv huab cua.Thaum cov ntsiab lus carbon ntau dua 0.2%, TiC nyuaj yuav tsim nyob rau hauv titanium alloy. Qhov kub thiab txias yog siab, txheej txheej tawv tawv ntawm TiN yuav tsim los ntawm kev sib cuam tshuam nrog N.Thaum qhov kub siab tshaj 600 ℃, titanium absorbs oxygen thiab tsim txheej txheej hardened nrog siab hardness.Raws li cov ntsiab lus hydrogen nce, ib txheej nkig yuav kuj form.Qhov tob ntawm cov tawv thiab nkig nto txheej tsim los ntawm kev nqus cov pa tuaj yeem ncav cuag 0.1 ~ 0.15 hli, thiab hardening degree yog 20% ~ 30%. nto.

Me me thermal conductivity elasticity

Lub thermal conductivity ntawm titanium (λ = 15.24W / (m·K)) yog hais txog 1/4 ntawm cov nickel, 1/5 ntawm cov hlau, 1/14 ntawm txhuas, thiab thermal conductivity ntawm ntau yam titanium Cov alloys yog li 50% qis dua li ntawm titanium.Qhov elastic modulus ntawm titanium alloy yog li ntawm 1/2 ntawm cov hlau, yog li nws cov rigidity tsis zoo, yooj yim rau deformation, yuav tsum tsis txhob ua los ntawm slender pas nrig thiab nyias-walled qhov chaw, txiav thaum Cov txheej txheem ntawm qhov rov qab yog qhov loj, txog 2 ~ 3 zaug ntawm cov hlau tsis muaj steel, ua rau muaj kev sib txhuam hnyav, adhesion, nplaum hnav ntawm cov cuab yeej nto.