Precision Poob Wax Investment Tuag Casting

Product Description

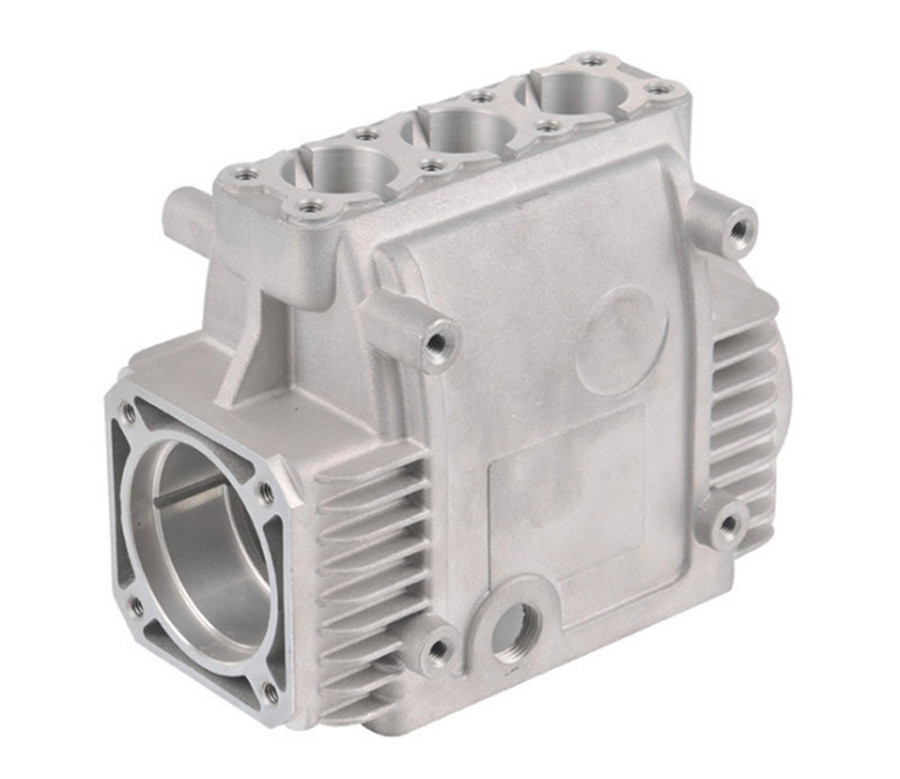

Peev Casting, tseem hu ua Poob Wax Casting, yog txheej txheem casting precision uas muab kev tsim qauv yooj yim thiab cov nqi tseem ceeb.

Kev nqis peev Casting txheej txheem cuam tshuam nrog cov hlau molten rau hauv pwm uas tau tsim los siv cov qauv siv quav ciab.Thaum cov pwm tsim, cov qauv siv quav ciab yog yaj thiab ntws tawm.Hollow cores tuaj yeem cuam tshuam los ntawm kev siv cov ntaub ntawv pov thawj kub uas tiv thaiv cov hlau molten los ntawm tag nrho cov pwm.

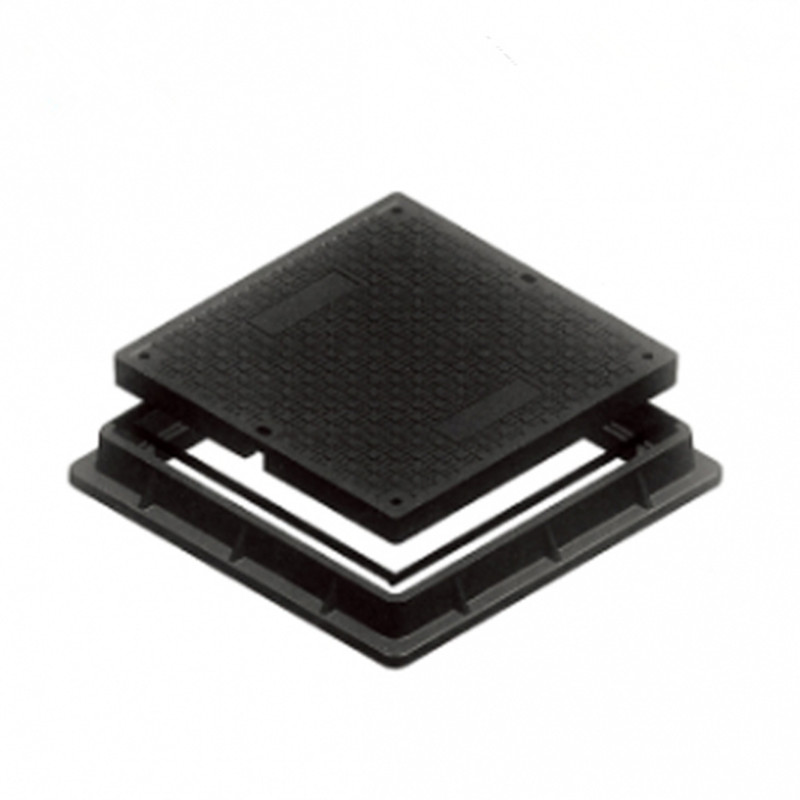

Peev Casting feem ntau yog siv rau me me castings, tab sis tuaj yeem siv los tsim cov khoom loj dua.

Dimensional kam rau ua ± 0.003 in./in.tau tiav tiav.Cov khoom me me nrog cov phab ntsa nyias li 0.025 nyob rau hauv. tuaj yeem ua tiav los ntawm peev casting.

Common Material Qib ntawmStainless hlau Casting

SIB 304:Feem ntau siv austenite hlau, tej zaum yuav raug xa mus rau A2 stainless.

SIB 316:Qhov thib ob feem ntau austenite hlau, kuj hu ua A4 stainless.SS316 feem ntau yog siv rau nws qhov kev tiv thaiv corrosion.

SS304L thiab SS316L(superaustenitic stainless hlau): Tus [L" txhais tau hais tias cov ntsiab lus ntawm cov hlau yog qis dua 0.03%, uas txo cov nyhuv rhiab heev tshwm sim los ntawm qhov kub siab koom nrog hauv vuam.Sib piv nrog 300 series, nws qhia tau hais tias zoo dua tiv thaiv kev ntxhov siab-corrosion tawg.

17-4 PHN:Feem ntau cov nag lossis daus-hardening martensitic stainless hlau, uas siv li ntawm 17% chromium thiab 4% npib tsib xee.

Kev kho deg ntawmStainless hlau Castings

Txhaj tshuaj tiv thaiv: Siv los tshem tawm cov tawv nqaij dub oxide tom qab casting ntawm stainless hlau khoom.

Pickling & Passivation Treatment: Pickling yog ib txoj hauv kev kho tshuaj los tshem tawm cov av hauv av xws li oxide tawv nqaij, xeb, vuam chaw, thiab lwm yam.Thiab passivation yog txheej txheem uas tsim cov txheej txheem tshiab chromium tiv thaiv, yog li txhawm rau txhim kho lub peev xwm los tiv thaiv oxidation ntawm stainless hlau castings.

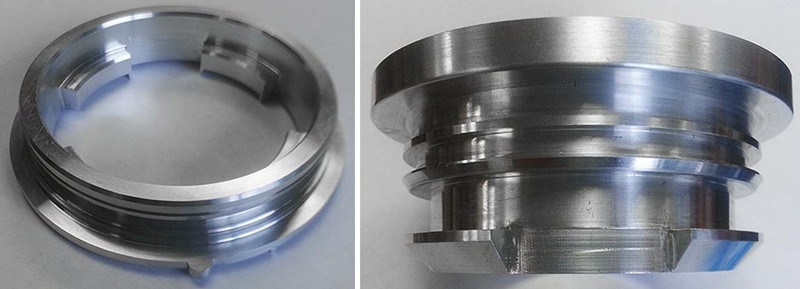

Electropolishing: Siv los tshem tawm qhov me me burrs thiab txhim kho qhov ci ntawm stainless hlau castings.

Daim iav Polishing: Ib hom kev polishing nto uas tuaj yeem ua tiav qhov du thiab ci ntsa iab zoo li daim iav tiav.

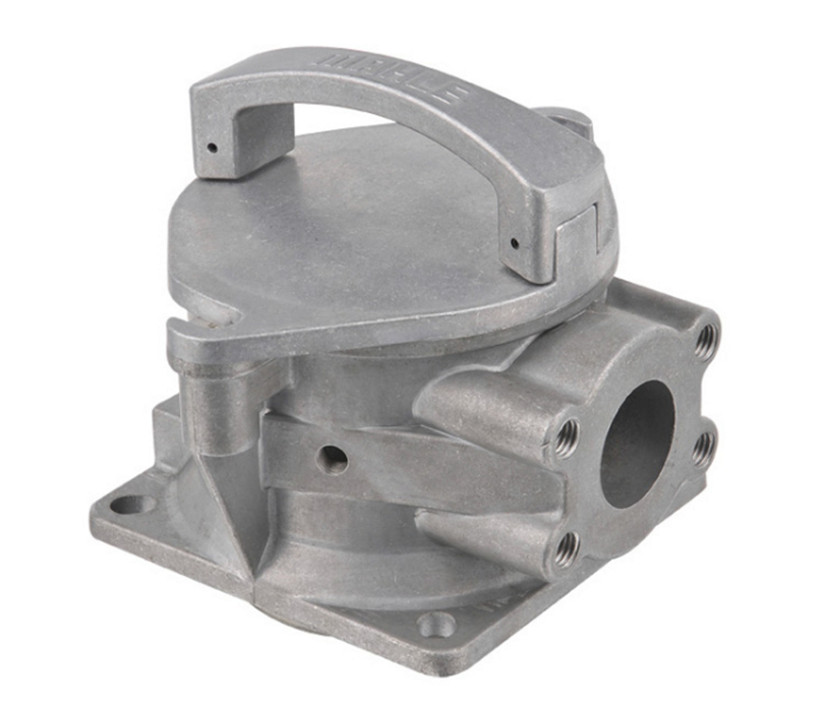

Daim ntawv thov ntawm Stainless hlau Castings

Rau qhov tshwj xeeb lub cev ntawm cov hlau tsis muaj steel, Stainless hlau castings tau txais kev pab rau ntau yam kev lag luam, tshwj xeeb tshaj yog nyob rau hauv ib puag ncig hnyav.Hauv qab no yog cov kev siv tseem ceeb ntawm stainless hlau casting

peb lub Hoobkas