Sheet Hlau Punching thiab Stamping Part

Product Description

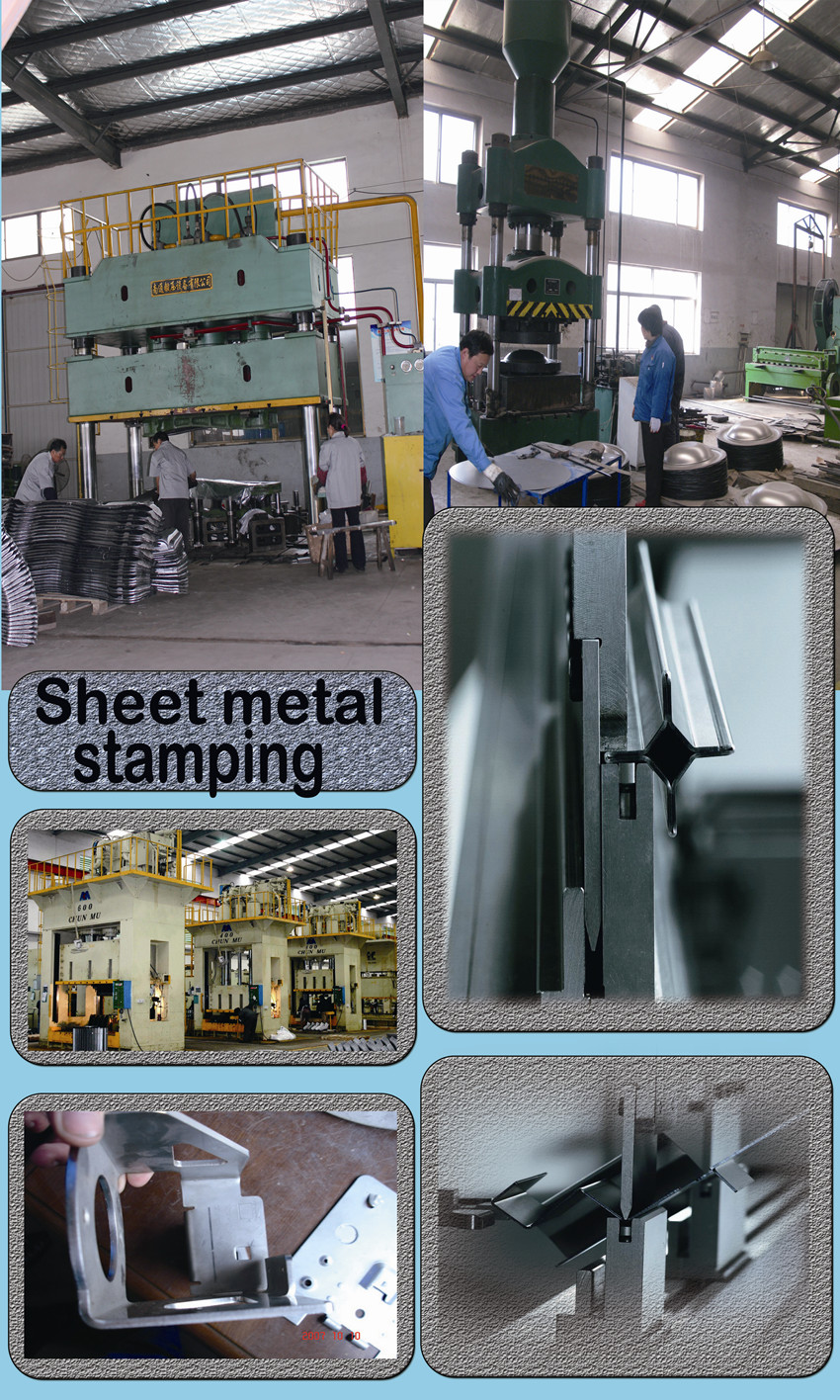

Stamping yog cov cuab yeej tsim khoom ntawm cov khoom lag luam nrog qee cov duab, qhov loj me thiab kev ua tau zoo los ntawm lub zog ntawm cov khoom siv los yog cov khoom tshwj xeeb stamping kom cov ntaub ntawv ncaj qha deformed thiab deformed hauv pwm.Sheet hlau, pwm thiab khoom siv yog peb lub ntsiab ntawm stamping.Stamping yog hlau txias deformation txheej txheem.Yog li ntawd, nws yog hu ua txias stamping los yog ntawv stamping, hu ua stamping.Nws yog ib qho ntawm cov txheej txheem tseem ceeb ntawm kev ua hlau yas (los yog kev ua haujlwm siab), thiab nws tseem koom nrog cov khoom tsim engineering technology.

Ntawm cov khoom siv hlau thoob ntiaj teb, 50 mus rau 60% yog ua los ntawm cov ntawv hlau, feem ntau yog nias thiab nias rau hauv cov khoom tiav.Lub cev ntawm lub tsheb, lub phaj radiator, lub nruas ntawm lub boiler, lub plhaub ntawm lub thawv, cov tub ntxhais hlau ntawm lub cev muaj zog thiab cov khoom siv hluav taws xob, thiab lwm yam yog tag nrho cov stamped thiab ua tiav.Kuj tseem muaj ntau qhov chaw stamping hauv cov khoom xws li cov cuab yeej ntsuas, cov khoom siv hauv tsev, cov tshuab ua haujlwm, thiab cov thawv ntim khoom.Stamping yog qhov ua tau zoo txav mus los coj cov qauv nyuaj, qhov tshwj xeeb yog ntau txoj haujlwm nce qib tuag, hauv xovxwm kom ua tiav ntau txoj haujlwm stamping, ua tiav cov khoom siv tsis siv neeg.Tsim kom muaj kev ceev ceev, lub sijhawm so ntev, Linqu tus nqi qis, kev sib koom ua ke Linqu ntau pua daim ib feeb, los ntawm ntau qhov kev cog qoob loo nyiam.

Stamping qhov chaw thiab castings thiab forgings muaj zog thiab muaj nyias, sib xws, lub teeb thiab muaj zog yam ntxwv.Stamping tuaj yeem tsim cov khoom ua haujlwm nrog kev txhawb nqa cov tav, tav, coils, lossis flange uas nyuaj rau kev tsim khoom nrog qhov kev paub tab ntawm tes kom nws rigidity.Vim qhov tsis kam ntawm cov pwm ntxhib, qhov tseeb ntawm cov khoom ua haujlwm tuaj yeem ncav cuag micrometers, thiab qhov tseeb thiab qhov tshwj xeeb yog tib yam.Lub qhov thiab tus thawj coj tuaj yeem xuas nrig tawm.Hauv kev tsim khoom tiag tiag, feem ntau siv thiab cov txheej txheem stamping zoo ib yam li qhov kev xeem, xws li kev ntsuas kev ua tau zoo, cov ntaub ntawv ntsuas kev ua tau zoo xws li stamping kev ua tau zoo los xyuas kom meej cov khoom tiav thiab siab dhau.

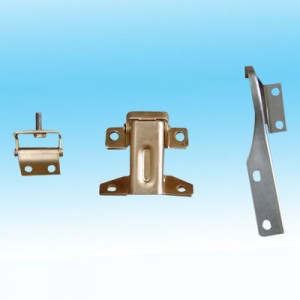

Cov khoom qhia